Poles & Fabrics used in Tents

While searching the specs for a old Mountain Hardwear 3.1 Arch 4 season tent I came across many useful information about the material used in tents like poles, fabrics etc.

Poles

Main Manufactures

DAC (Dongah Aluminum Corporation): Used in TNF, Hilleberg & Seirra Design tents.

Easton: 7075-T9 Aluminum Tent Pole used in earlier Mountain Hardwear tents like Trango 3.1 Arch. Easton poles used by US army and in all expeditions on everest.

Yunan Aluminium: Atlas Tent poles used in all Mountain Hardwear tents.

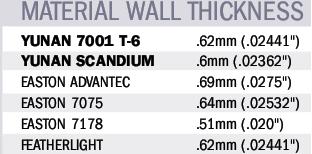

More brands changed from Easton to DAC. Hilleberg changed from Easton to DAC. The specs of DAC are also slightly better than Easton. But just slightly… Scandium poles of Yunan have better specs than DAC but are a bit more heavy. Here’s a comparison chart from Mountain HW brochure:

Source for Tent Poles

Shelby for DAC, TentPoles Technologies for Easton, Quest Outfitters for Poles & other misc. items.

Now something on the Fabric used in the Tents

Nylon and Polyster are used for the fabrics. Tent Fabrics can have the following characteristics:

- Denier (d): measures the weight of fabric in grams per 1000-meter length. So for instance, 60d signifies a weight of 60 grams per 1000 meter of the thread used in the fabric. Lightweight fabrics would be about 50d.

- Water resistance (psi): measures the weight of water that can exert pressure on a square inch of the fabric without leaking. It is measured in pounds per square inch (psi). A good fly sheet would be 80psi.

Tent covers/Fly sheet:

- Polyurethane Coating: This is coating applied on the tent fabric to make it more durable and waterproof. Multiple number of coatings or ‘passes’ determine the added protection but at the cost of extra weight.

- Waterproof/breathable laminates: Tent cover uses a layering system of different materials to form a strong and waterproof but breathable fabric. Common laminates are GoreTex, ToddText, Klimate, and MemBrain.

- Ripstop: This is a polyester taffeta with thicker threads weaved into the material at regular intervals. Thicker threads will prevent small rips in the Tent to get worse.

- Clear Film: This is a see through material often used for windows and skylights.

This link has some details on the tent material.

Nylon or Polyster:

Polyester fabrics perform better than nylon for moisture management because polyester is more hydrophobic. Nylon threads will absorb more water than Polyester, water requires more heat energy to warm than does air, so nylon will feel colder when wet, and stay wet longer, and when saturated impede breathability.

Mountain Hardwear uses Polyster in Fly Sheets, Seirra Designs uses Nylon more information on Fabrics at Seirra Designs

BTW: Mountain Hardwear was founded by people from Seirra Designs.

More on the trekking stuff later.

Thank you! Information about tent poles is not the easiest to find.

Wayne